Page 15 - Arrow Shark X-60 Owner Manual

P. 15

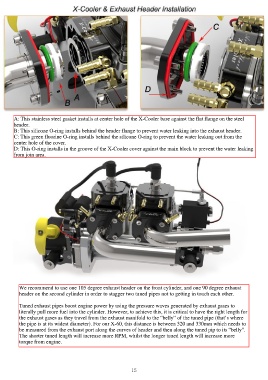

A: This stainless steel gasket installs at center hole of the X-Cooler base against the flat flange on the steel

header.

B: This silicone O-ring installs behind the header flange to prevent water leaking into the exhaust header.

C: This green fluorine O-ring installs behind the silicone O-ring to prevent the water leaking out from the

center hole of the cover.

D: This O-ring installs in the groove of the X-Cooler cover against the main block to prevent the water leaking

from join area.

We recommend to use one 105 degree exhaust header on the front cylinder, and one 90 degree exhaust

header on the second cylinder in order to stagger two tuned pipes not to getting in touch each other.

Tuned exhaust pipes boost engine power by using the pressure waves generated by exhaust gases to

literally pull more fuel into the cylinder. However, to achieve this, it is critical to have the right length for

the exhaust gases as they travel from the exhaust manifold to the “belly” of the tuned pipe (that’s where

the pipe is at its widest diameter). For our X-60, this distance is between 320 and 330mm which needs to

be measured from the exhaust port along the curves of header and then along the tuned pip to its “belly”.

The shorter tuned length will increase more RPM, whilst the longer tuned length will increase more

torque from engine.

15