Page 20 - Arrow Shark X-60 Owner Manual

P. 20

A: Low-Speed Needle

If the engine is easy to start, and idles a little rough (rich), and responds well when you open the throttle

with a brief show of smoke through the exhaust, then the low speed needle is close to being correct. If the

engine tends to hesitate or bog down when you open the throttle quickly (especially when the engine is

cold), or if the idle speed is too high even with the throttle barrel nearly closed, the low speed needle is

probably to lean and you need to screw it out (1/8 of a turn at a time). If the engine floods easily and is

hard to start, the low speed needle is probably set to rich and you need to screw it in slightly.

B: High-Speed Needle

When this needle is correctly set, the engine will run cleanly, accelerate well from half throttle without

hesitation, and will not lose RPMs during turns. It is tempting to lean the high speed needle to optimize

the mixture for peak power and on-water RPM, but going too lean can be risky as the engine will suffer

from overheating and reduced lubrication. This can lead to damage or shorter life for your engine. If the

engine stops or loses RPMs when your boat is running on the water, the high speed needle is probably

set too lean and you need to screw it out slightly. If the engine is not running cleanly and seems to

hesitate or not reach peak RPMs, then the high speed needle is probably set too rich and you need to

screw it in slightly. Running with a slightly rich mixture may cause a small drop in top speed, but it will

allow your engine to run cooler and with good lubrication for reliability and long life.

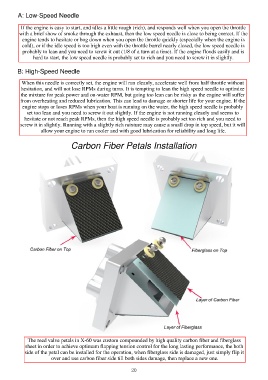

Carbon Fiber Petals Installation

The reed valve petals in X-60 was custom compounded by high quality carbon fiber and fiberglass

sheet in order to achieve optimum flapping tension control for the long lasting performance, the both

side of the petal can be installed for the operation, when fiberglass side is damaged, just simply flip it

over and use carbon fiber side till both sides damage, then replace a new one.

20