Page 15 - Arrow Shark 2020 RC Boats

P. 15

Break-In Engine

To ensure long life and good performance from your engine, you MUST break it in properly. To obtain

the optimum fuel for your engine, mix 87 or 90 Octane regular pump gas with 100% Synthetic Quality

oil at a ratio of 16:1 (6% oil). Another choice for oil is quality marine outboard engine oil. Operate your

engine at about 1/2 to 3/4 maximum throttle opening during the break-in process. DO NOT run at full

throttle while breaking in your engine. Patience is very important here; the boat will run more slowly

during the break-in process and the engine’s output power will increase gradually over the first 3-4 tanks

of fuel. Once the engine is broken in, the power will increase substantially.

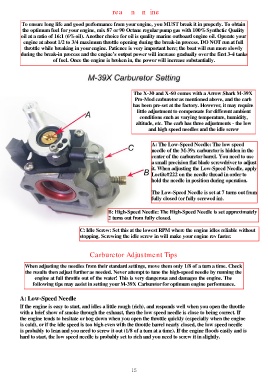

The X-30 and X-60 comes with a Arrow Shark M-39X

Pro-Mod carburetor as mentioned above, and the carb

has been pre-set at the factory. However, it may require

little adjustment to compensate for different ambient

conditions such as varying temperature, humidity,

altitude, etc. The carb has three adjustments - the low

and high speed needles and the idle screw

A: The Low-Speed Needle: The low speed

needle of the M-39x carburetor is hidden in the

center of the carburetor barrel. You need to use

a small precision flat blade screwdriver to adjust

it. When adjusting the Low-Speed Needle, apply

Loctite#222 on the needle thread in order to

hold the needle in position during operation.

The Low-Speed Needle is set at 7 turns out from

fully closed (or fully screwed in).

B: High-Speed Needle: The High-Speed Needle is set approximately

2 turns out from fully closed.

C: Idle Screw: Set this at the lowest RPM where the engine idles reliable without

stopping. Screwing the idle screw in will make your engine rev faster.

Carburetor Adjustment Tips

When adjusting the needles from their standard settings, move them only 1/8 of a turn a time. Check

the results then adjust further as needed. Never attempt to tune the high-speed needle by running the

engine at full throttle out of the water! This is very dangerous and damages the engine. The

following tips may assist in setting your M-39X Carburetor for optimum engine performance.

A: LowSpeed Needle

If the engine is easy to start, and idles a little rough (rich), and responds well when you open the throttle

with a brief show of smoke through the exhaust, then the low speed needle is close to being correct. If

the engine tends to hesitate or bog down when you open the throttle quickly (especially when the engine

is cold), or if the idle speed is too high even with the throttle barrel nearly closed, the low speed needle

is probably to lean and you need to screw it out (1/8 of a turn at a time). If the engine floods easily and is

hard to start, the low speed needle is probably set to rich and you need to screw it in slightly.

15